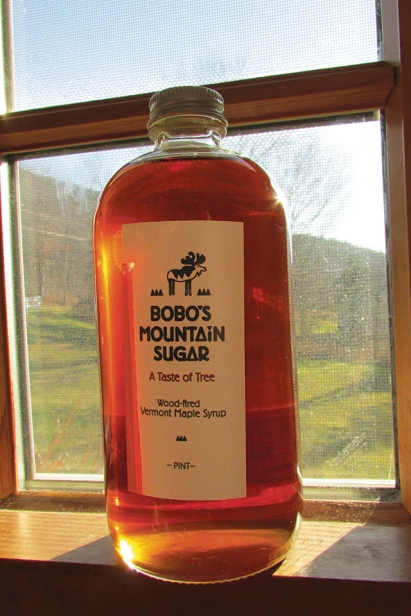

Bobo’s Mountain Sugar

From Boiler to Bottle

On the sugarhouse wall hangs a black and white photograph of a man in a wool hat, vest and thick boots, surrounded by galvanized tubs and old milk cans. He’s sitting in front of a steaming sap evaporator, and his relaxed demeanor indicates he’s been there a while. Which is precisely what happens when you transform sap into maple syrup. You sit and wait. Then wait some more.

“That’s my father-in-law, who used to make syrup on this property 30 years ago,” says Tina Hartell, who runs Bobo’s Mountain Sugar in Weston with her husband, Skye Chalmers. “This land has been in Skye’s family since the mid-1950s, and Skye always wanted to settle here.” The rocky wooded hillside faces south to Magic, Stratton and Bromley mountains. Prime sugaring land with a steep slope and enormous 150-year-old maples.

Skye and Tina were married in 2006, bought 40 acres of sugar bush from Skye’s dad in 2008 and built the sugarhouse in 2012. “We spent that first year setting up the infrastructure. Our production began the winter of 2013.” It was a pretty steep learning curve, but Tina’s background teaching chemistry and environmental science at the Mountain School in Vershire certainly helped. “The school had a sugarhouse, so I had a good idea of what I was getting into, and Skye had some experience as well.”

Tina oversees the operation at Bobo’s, and Skye helps out with firewood and boiling come spring. Aside from the intense three weeks of boiling, she spends about 20 hours a week managing the business, which allows her time for their five-year-old twins, Wren and Aida. “From May through December, I bottle, package, market and ship my product. Come November, when the leaves are down, I focus on the woods work, which I love. That means removing trees that fell on the lines during the summer and assessing any damage critters may have done.” Tina brings on another friend, Bobbie Jean Booth, who assists with the outdoor work come deep winter. “It’s essentially a two-woman job in February and March as we get the system ready to go.”

Want to learn what happens next? Pick up the current issue of Edible Green Mountains.

Maria Reade spent a day last February repairing lines and setting taps with Tina and Bobbie Jean. She definitely drenched her pancakes in dark robust the next morning.